Xingte automatic needle motor winding machine for with dual work

station XT-02D

Needle Winding:

Needle winding is a preferred method for producing internally or

externally wound stators or rotors with intricate winding patterns

and pole chains, such as Singletooth Winding.

In the needle winding process, a needle (nozzle) that dispenses

wire moves horizontally or vertically along the pole, encircling it

as it winds the wire.

This method offers a high level of flexibility in handling various

products and processes compared to other techniques. Xingte's

needle winding machines can handle multiple products

simultaneously, achieving high operating speeds while maintaining

process reliability.

Xingte offers a range of needle winding machines tailored for

specific products, including machines for winding 2-pole stators or

cam-operated winding machines that use multiple needles

simultaneously to maximize throughput.

The needle motor winding machine Product Features

Flexibility (internal and external rotor)

Multi-parts winding at the same time

Freely programmable

Wire layering

Freely programmable contacting/wire termination (teach process)

High filling factors despite required space for needle

Large wire diameter range

Freely selectable wire connections even on the lower side of the

stator

Low tooling costs

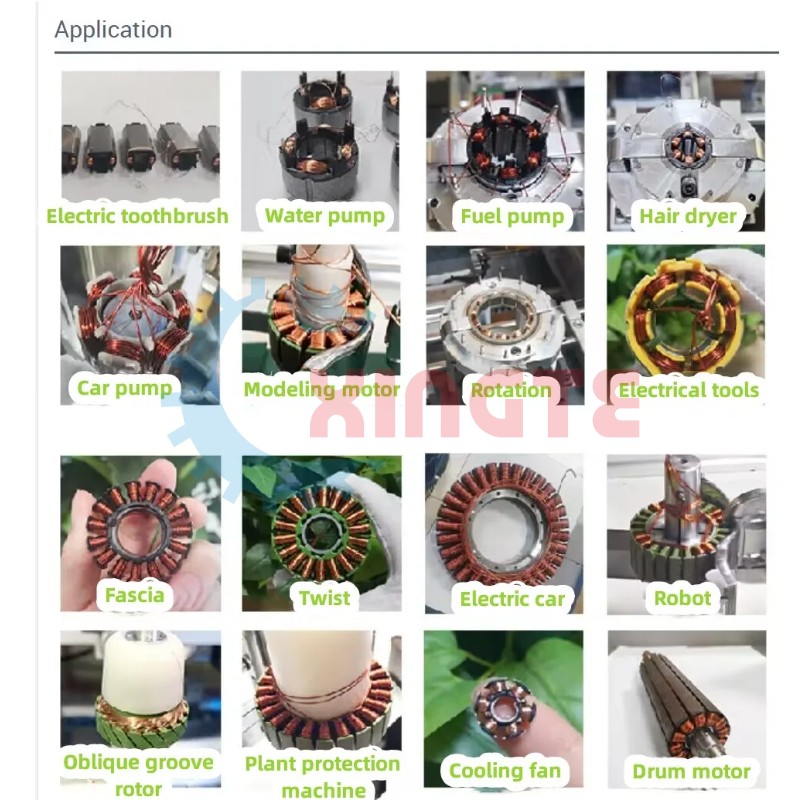

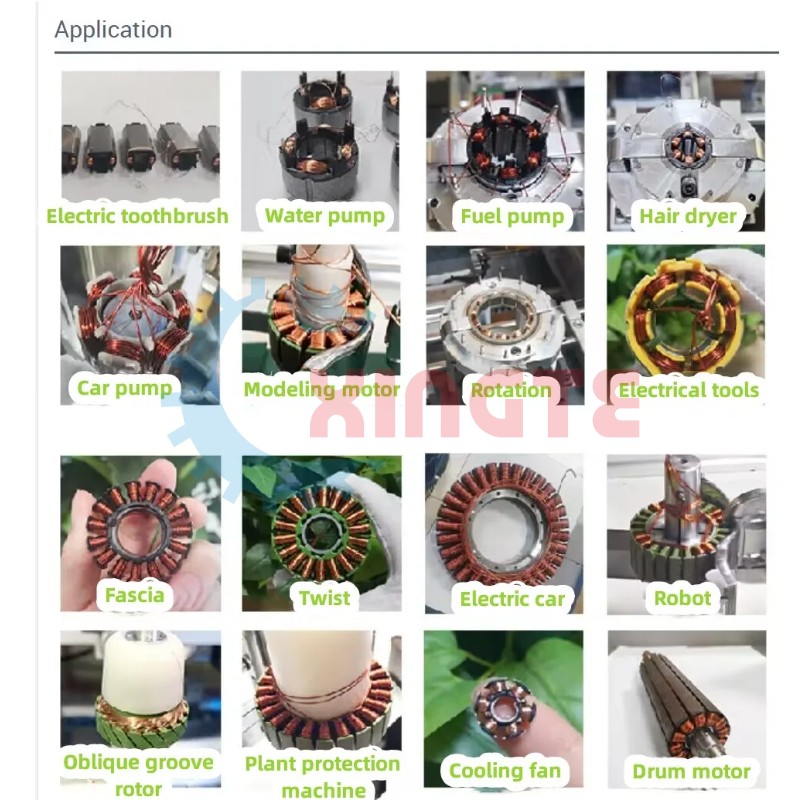

Typical products where Needle Winding is used

Pump drives

Fans

Power steering, servo motors

various brushless motors

Professional food processors

Professional power tools

Coolant pumps

Heating pumps

Vacuum pumps

Oil pumps

Roller shutter drives

Wheelchair drives

Dental drill

WIRE GUIDE TUBE POSITIONING

Wire guide tube positioning is an important aspect of XT-02D's

basic configuration. By default, the wire guide tube is fixed

horizontally. However, as an optional feature, a motorized tilting

movement can be applied to allow for both upper and lower routing,

making the wrapping and routing operations much simpler. This

tilting movement can be programmed to any position between +90° to

-70°.

Needle Winding

Needle winding is the process of choice for the production of

internally or externally wound stators or rotors with a complex

winding scheme and pole chains (see Singletooth Winding).

During the needle winding process, the needle (nozzle) that feeds

the wire is moved horizontally or vertically along the pole. It

thereby "circles" the pole and winds it.

In terms of the products and processes to be handled, this method

offers a comparatively high degree of flexibility compared to

others. The needle winding machines from XINGTE are able to process

several different products simultaneously in one and the same

machine. They achieve very high operating speeds by exploiting the

physical possibilities without negative effects on process

reliability.

XINGTE provides a wide variety of needle winding machines required

for special products, e.g. for winding 2-pole stators or

cam-operated winding machines where several needles can be used

simultaneously to enable maximum throughput.

TENSIONER CLOSED TO NEEDLE

A correct wire tension is essential to grand winding quality. The

best way to do this is to install the tensioners close to the

winding process. For this reason, XINGTE designs their machines

with tensioners next to the needle.

Moreover, it is possible to have two different types of tensioners

for each head to manage two different wire tension ranges. This

option allows fast retooling and also the winding of an extended

wire range.

Product parameter

| Model number: | XT-02D |

| Wire Diameter : | 0.1 ~ Ø1.6mm |

| Stator Outer diameter: | Max 106mm |

| Stator inner diameter: | 10mm |

| Stator stack thickness : | 150mm |

| Winding method: | needle winding |

| Winding station: | 2 stations |

| Power: | 6KW |

| Power supply: | AC380V,50/60Hz |

| Air pressure: | > 0.6Mpa |

| Winding speed: | 1200Rpm |

| Machine dimension: | (L)1500 *(W)680*(H)1990 mm |

| G. W: | 600KGS |

The stator is stationary during winding. All needle movements are

motorized and programmable and managed in direct drive mode (no cam

system, no belts, no lead screw).

It is possible to wind:

- Inner straight slot stators

- Inner skewed slot stators

- Outer stators straight and skewed slot

Product parameters

Model number: | XT-02D

|

| Wire Diameter : | 0.1 ~ Ø1.6mm

|

| Stator Outer diameter: | Max 106mm

|

| Stator inner diameter: | 10mm

|

| Stator stack thickness : | 150mm

|

| Winding method: | needle winding

|

| Winding station: | 2 stations

|

| Power: | 6KW

|

| Power supply: | AC380V,50/60Hz

|

| Air pressure: | > 0.6Mpa

|

| Winding speed: | 1200Rpm

|

| Machine dimension: | (L)1500 *(W)680*(H)1990 mm

|

| G. W: | 600KGS

|

Different tooling configurations are available, on request, to make

the machine suitable for all applications.

WINDING SPEED DIAGRAM

The head speed can reach up to 1200 rpm, in particular conditions

of stator geometry and wire size.

THE XT-02D PLATFORM

This machine is part of a wider range of needle-winding machines

developed and manufactured by XINGTE.

Inside this range, we can also offer:

1, Motor stator, rotor, and other related coil winding machine

2, Transformer-related product coil winding machine

3, voice coil-related product winding machine

4, inductor coil winding machine and

5, customized fully automatic line for the motor, speaker,

transformer production line

About Xingte

Established in 2007, XINGTE boasts over 17 years of R&D

experience in the coil winding area. The company is headquartered

in Shenzhen, with a factory area exceeding 30,000 square meters,

ensuring strong productivity. With over 230 technical services and

after-sales staff, XINGTE provides worry-free after-sales service

at worldwide service points. XINGTE has obtained 120+ patents and

related certificates. The company's workforce of over 600

experienced employees guarantees production capacity and fast

delivery. Additionally, XINGTE's team of over 130 experienced

engineers ensures strong R&D ability and customization

capability.

Pictures of Our Factory

Our machine pictures

Stator coil samples

Order process

Delivery

Our partenrs